Enhance your branding with custom printed stickers and labels.

Stickers & Labels Printing in Singapore

Stickers & Labels Printing in Singapore

High-quality sticker and label printing tailored for packaging, promotions, and product branding. Choose from a wide range of materials, finishes, and cutting options to create stickers and labels that are durable, visually appealing, and suited for various applications.

Explore All Your Sticker & Label Options

From classic name cards to premium specialty designs, our business card printing options are designed to suit every industry and budget. Whether you need standard cards for daily use or standout designs for special occasions, you’ll find the right solution here.

Vinyl Cut-out Stickers

Transparent Stickers

Roll Stickers

Outdoor Label Stickers

Embossed Business Cards

Custom Label Stickers

Waterproof Label Stickers

Holographic Stickers

Security Stickers

-

Vinyl Cut-out StickersVinyl cut-out stickers are designed for bold branding, signage, and decorative applications. Made from...$0.00

Vinyl Cut-out StickersVinyl cut-out stickers are designed for bold branding, signage, and decorative applications. Made from...$0.00 -

Transparent StickersTransparent stickers are suitable for branding, packaging, and labelling applications where a clean,...$0.00

Transparent StickersTransparent stickers are suitable for branding, packaging, and labelling applications where a clean,...$0.00 -

Roll StickersCustom roll stickers are supplied on rolls for efficient application, making them ideal for packaging,...$0.00

Roll StickersCustom roll stickers are supplied on rolls for efficient application, making them ideal for packaging,...$0.00 -

Outdoor Label StickersCustom Outdoor Label Stickers are designed for labelling and branding applications that require improved...$0.00

Outdoor Label StickersCustom Outdoor Label Stickers are designed for labelling and branding applications that require improved...$0.00 -

Embossed Business CardsOur Embossed Business Cards offer a premium, tactile experience that helps your brand stand out. With...$49.00

Embossed Business CardsOur Embossed Business Cards offer a premium, tactile experience that helps your brand stand out. With...$49.00 -

Custom Label StickersCustom label stickers for general product labelling, packaging, and branding. Supplied on sheets and...$0.00

Custom Label StickersCustom label stickers for general product labelling, packaging, and branding. Supplied on sheets and...$0.00 -

Waterproof Label StickersWaterproof label stickers are designed for applications that require resistance to moisture, spills, and l...$0.00

Waterproof Label StickersWaterproof label stickers are designed for applications that require resistance to moisture, spills, and l...$0.00 -

Holographic StickersHolographic stickers feature a reflective, colour-shifting surface that creates a striking visual effect....$0.00

Holographic StickersHolographic stickers feature a reflective, colour-shifting surface that creates a striking visual effect....$0.00 -

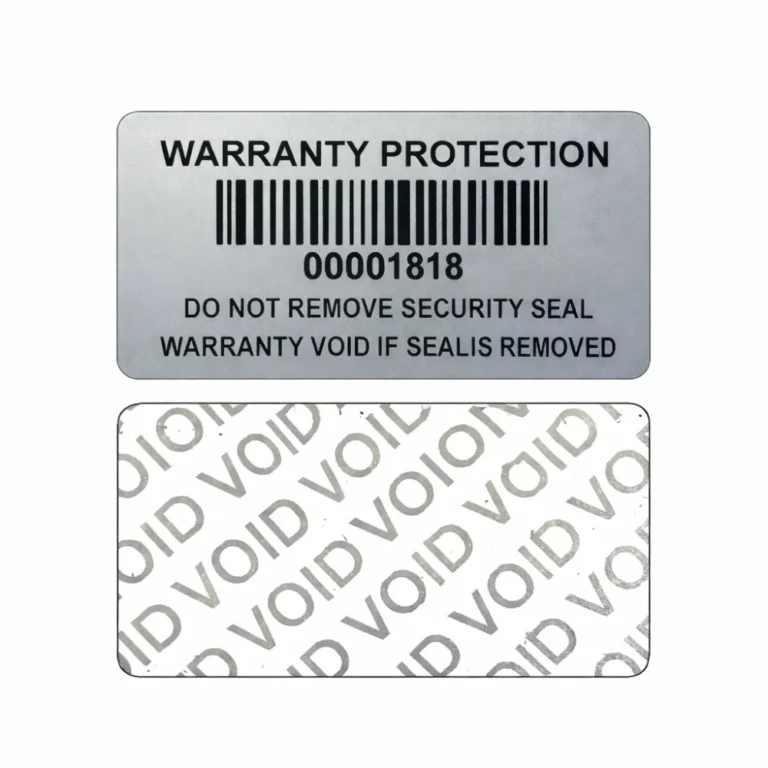

Security StickersSecurity stickers are designed for tamper-evident applications where protection, authentication, and...$0.00

Security StickersSecurity stickers are designed for tamper-evident applications where protection, authentication, and...$0.00

Compare Materials & Finishes

Different sticker materials and finishing options serve different purposes. Compare materials, surfaces, and cutting styles to find the right solution for your packaging, promotions, or product labelling needs.

Paper Stickers

Gloss Finish

Matt Finish

Waterproof Stickers

Holographic Stickers

Kraft Paper Stickers

Vinyl Stickers

Transparent Stickers

Security Void Stickers

Die-Cut Shape

Kiss-Cut

Loose Piece

Why Printing.com.sg

Reliable Sticker & Label Printing for Brand Visibility

High-quality sticker and label printing designed to support branding, packaging, and promotional applications with precision.

PRINT Smart

Our stickers and labels deliver vibrant colours, clean cutting, and durable materials that help your branding stand out across products and surfaces.

PRINT with Confidence

Each sticker and label is produced using trusted materials and precise finishing methods to ensure consistency and durability.

PRINT Made Simple

Select your material, finish, and quantity easily through our online platform with clear specifications and production guidance.

PRINT for Growth

From small runs to large-scale production, our sticker and label printing solutions grow with your business requirements.

Trusted by Businesses Across Singapore

Genuine feedback from businesses who print with confidence.

“Printing.com.sg makes our lives so much easier. Their online ordering system is simple and efficient, and the print quality is always excellent. I wouldn’t go anywhere else.”

“Printing.com.sg has been a game-changer for us. Their fast turnaround and quality prints help us maintain a professional image. We’ve never missed a deadline since partnering with them!”

“We needed business cards urgently, and Printing.com.sg delivered on time without compromising quality. The finish is flawless, and my clients have already complimented the design!”

Ready to Print Custom Stickers & Labels?

Select your material, shape, and finish to create stickers and labels that enhance your branding and packaging.

Frequently Asked Questions

Category: Stickers & Labels FAQs

What’s the difference between die-cut and kiss-cut stickers?

The main difference between die-cut and kiss-cut stickers lies in how the sticker is cut and how it is used.

Die-cut stickers are cut all the way through both the sticker material and the backing paper. Each sticker is separated individually and ready to use. This option is ideal when you want:

- Single, standalone stickers

- Custom shapes that match your artwork exactly

- Stickers for giveaways, packaging inserts, or retail distribution

Kiss-cut stickers are cut only through the sticker layer, while the backing paper remains intact. This leaves the sticker attached to a larger backing sheet, making it easier to peel. Kiss-cut stickers are commonly used when:

- Multiple stickers are placed on one sheet

- Easy peeling and storage are important

- Stickers are applied manually in batches

In summary, die-cut stickers offer a clean, individual finish, while kiss-cut stickers provide convenience and efficiency during application. The best choice depends on how the stickers will be distributed and applied.

What artwork format is required for stickers and labels?

For best print quality, artwork should be supplied as a print-ready PDF with:

- Correct dimensions and bleed

- High-resolution images (300 DPI)

- Fonts outlined or embedded

- Colour mode set according to print specifications

Vector files such as AI or EPS are also suitable, especially for custom shapes and die-cut designs.

Can stickers be supplied on sheets or rolls?

Yes, stickers can be supplied either on sheets or rolls, depending on how they will be used:

- Sheet stickers are ideal for hand application and smaller quantities

- Roll stickers are suitable for high-volume applications, automated labelling, or faster manual application

The best format depends on your production workflow and usage environment.

Do you offer custom shapes and die-cutting?

Yes, custom shapes and die-cutting are available to match your design requirements. Labels and stickers can be cut to standard shapes such as circles or rounded corners, or fully customised to follow unique artwork outlines.

Die-cutting allows greater design flexibility and is commonly used for branding, packaging, and promotional applications where visual impact is important.

Will stickers and labels leave a residue when removed?

Residue is influenced by adhesive strength, surface type, and how long the label remains applied.

- Removable adhesives are designed to minimise residue when removed within a recommended time frame

- Permanent adhesives may leave residue, especially after long-term use or exposure to heat and moisture

Proper material selection and application guidance help reduce residue concerns.

Are your stickers and labels easy to remove?

Ease of removal depends on the material and adhesive type used. Some stickers are designed with permanent adhesives for long-term applications, while others use removable or low-tack adhesives that allow clean removal.

If labels are intended for short-term promotions, temporary packaging, or reusable containers, selecting a removable adhesive helps prevent damage to the surface during removal.

What are the most common packaging products to put labels and stickers on?

Labels and stickers are widely used across many packaging types, including:

- Bottles and jars (food, beverages, cosmetics)

- Boxes and cartons

- Plastic containers and pouches

- Glass packaging

- Mailing and shipping materials

The choice of label material and adhesive should match the packaging surface and usage conditions to ensure proper adhesion and long-term performance.

Can I write on my personalised label stickers?

Yes, writing on label stickers is possible, depending on the material and finish selected.

- Uncoated or matte paper labels are generally easier to write on using pens or markers

- Glossy or laminated labels may require permanent markers or may not be suitable for handwriting

If you plan to add handwritten information such as batch numbers, dates, or notes, choosing a writable surface is recommended during material selection.

How can I avoid bubbles when applying label stickers?

Air bubbles typically occur due to uneven application or trapped air. To minimise this:

- Apply labels slowly from one edge to the other

- Use a flat applicator or card to smooth the label as it’s applied

- Avoid applying labels on cold or uneven surfaces

- Ensure labels and packaging are at room temperature

For large labels, applying from the centre outward can also help reduce air pockets.

How can I keep custom sticker labels from peeling?

Preventing labels from peeling starts with choosing the right material, adhesive, and surface preparation. To improve adhesion:

- Use materials suited to the application environment (e.g. vinyl for moisture or temperature changes)

- Ensure the surface is clean, dry, and free of dust or oil before application

- Apply firm, even pressure across the label, especially along edges

For packaging exposed to refrigeration, handling, or humidity, stronger adhesives and laminated finishes help improve durability and longevity.

Can you print custom-shaped sticker labels?

Yes, custom-shaped sticker labels are available through precision die-cutting. This allows labels to be cut to virtually any shape that follows your artwork outline—such as circles, rounded corners, contours around logos, or fully custom designs.

Custom-shaped labels are commonly used to enhance brand identity, improve shelf appeal, and create a more premium look compared to standard rectangular labels. The final shape is cut after printing, ensuring clean edges and consistent sizing across all labels.

Professional Sticker & Label Printing in Singapore

Professional sticker and label printing solutions designed for businesses across Singapore. Our stickers and labels are produced using a wide range of materials and finishes to suit packaging, branding, promotions, and product labelling needs. From paper and vinyl stickers to waterproof, transparent, and security labels, we deliver reliable print quality with precision and consistency for every application.